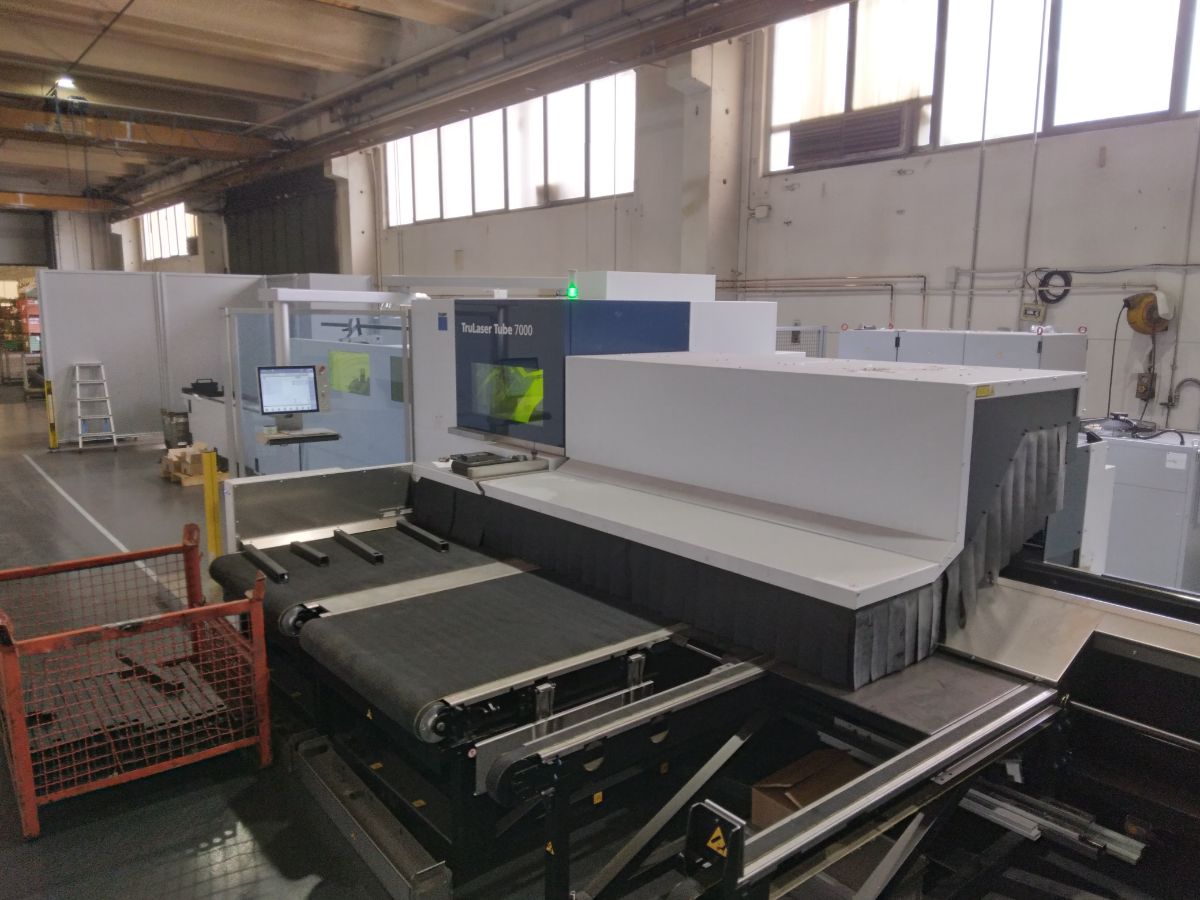

Photogallery tube laser processing

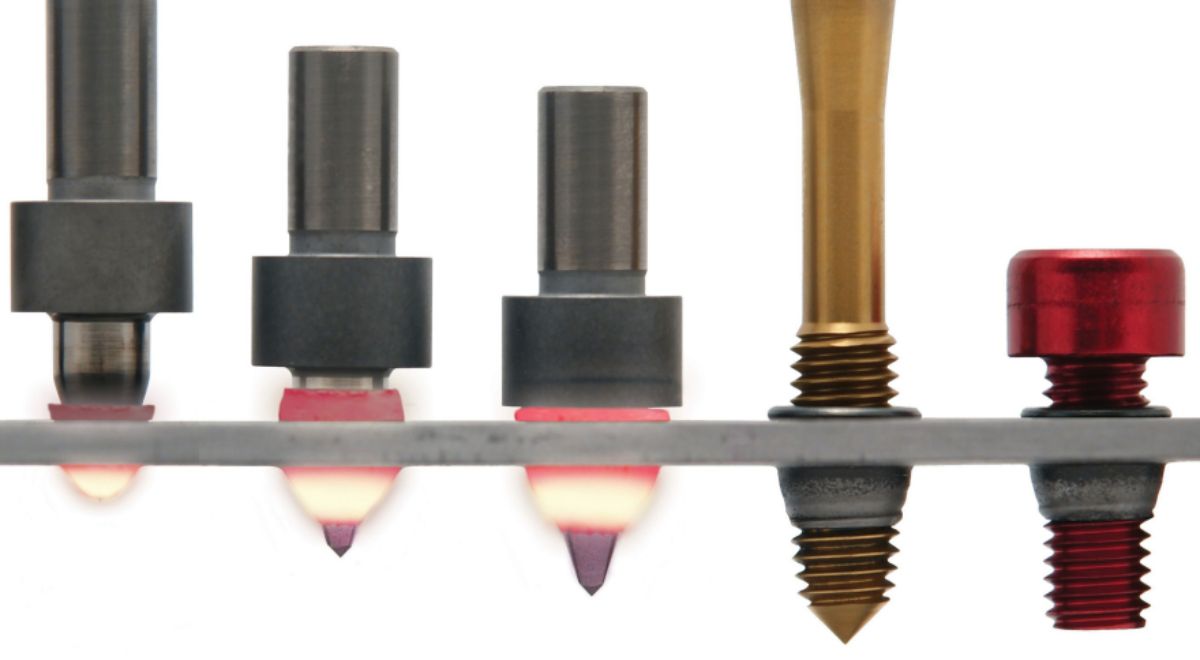

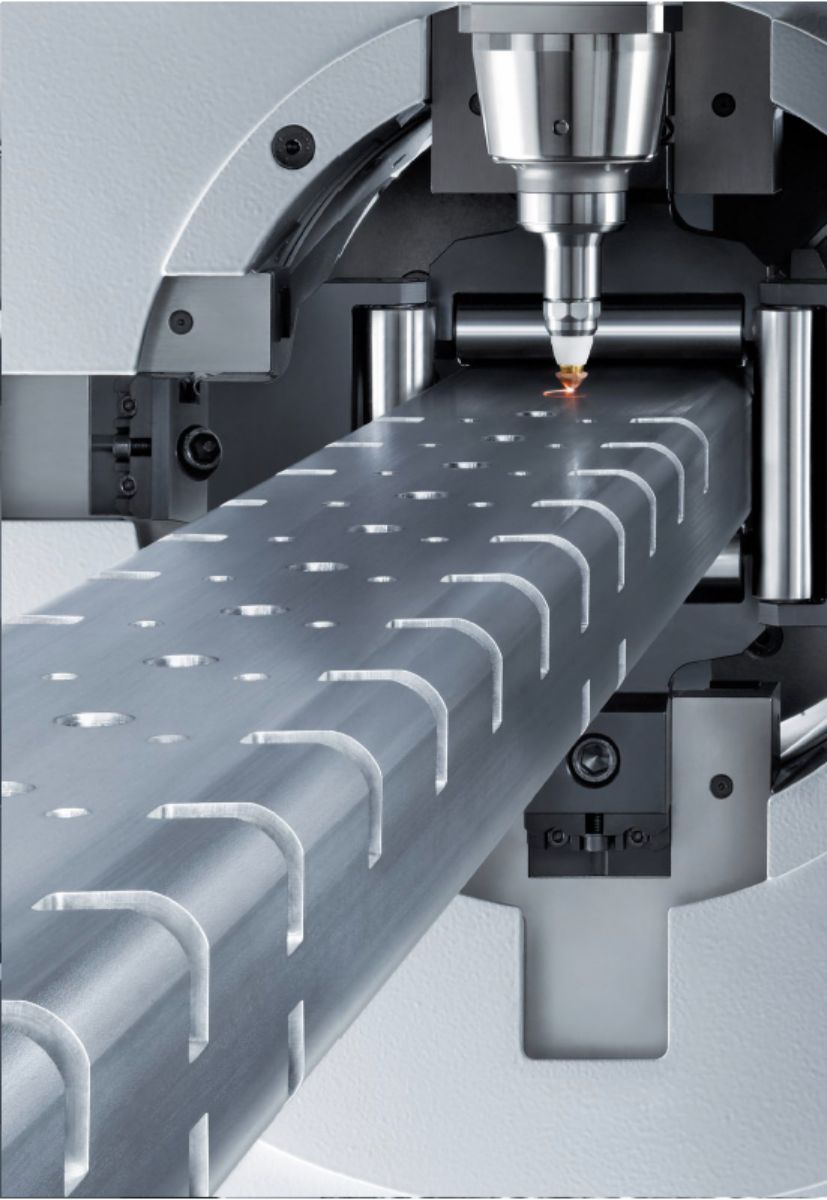

Below we illustrate a series of images representing special processing carried out by Officine Ceglia with the Tube laser for third parties. Example of Flowdrill flow drilling system (allows the creation of reinforced holes on tubes or sheets without the use of additional material and without chip removal).

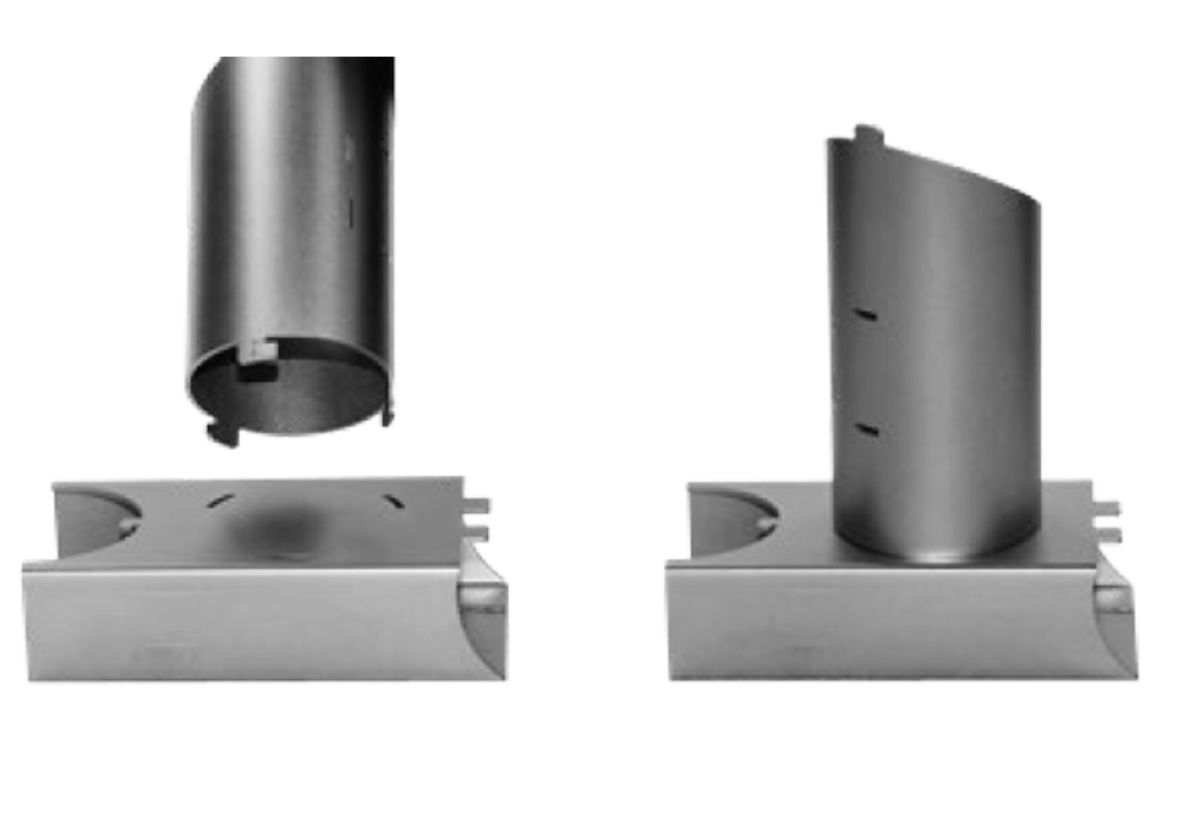

Processing of mechanical parts with a round section ø254 mm, maximum square section side 254 mm.

Processing of mechanical parts with a round section ø254 mm, maximum square section side 254 mm.